The IDIS Smart Factory assembles the varied components of the IDIS Total Solution utilizing a “smart” flexible production system. This leverages big data to modularize and refine production processes, allowing it to easily meet the company’s requirements at any given time. Each process in the IDIS Smart Factory is computerized — from material warehousing to management, production, function tests and even packaging — resulting in increased productivity. In addition, real-time production planning, cause-of-defect analysis, and tracking are achieved through the analysis of process histories.

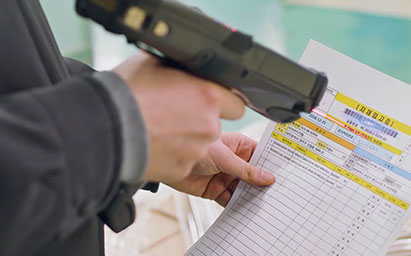

From the first step, barcodes enhance tracking and control, supporting alarms to ensure assembly proceeds according to strict standards. The automation and tracking further enhance calibration and testing as products move through the manufacturing cycle, while related processes enable close watch and intervention by IDIS employees when required. With the computerization of the automatic processes in the IDIS Smart Factory, if a certain product is missing materials or doesn’t pass a functionality test, it does not proceed to the next stage. This blocks any possible defects and enhances both productivity and customer satisfaction by improving the speed, quality, and consistency of the IDIS offering.

- From the first step in our manufacturing lifecycle to the last, barcodes enable real time tracking, monitoring, and process control.

- Continuous capture of production data ensures real-time issue mitigation and ongoing refinement of processes for optimal productivity.

- Small batch production ensures high quality without increasing costs, enabling closer attention to detail and rapid identification and resolution of issues with minimal production impact.

- The increased flexibility of small batch production allows for continuous improvement and adjustment, allowing IDIS manufacturing processes to be fully responsive to our customers' needs.

- Rigorous and meticulous testing, together with tightly controlled processes, guarantee IDIS’s signature quality, reliability, and performance (and allow for our industry-leading warranties).

- The integration of technology and manufacturing best practices in the IDIS Smart Factory boosts production and reduces defects, improving quality and consistency in the manufacturing lifecycle.

In 2018, IDIS was honored with a presidential citation in the 42nd National Productivity Competition (sponsored by the South Korean Ministry of Trade, Industry and Energy) for the company’s custom designed IDIS Smart Factory